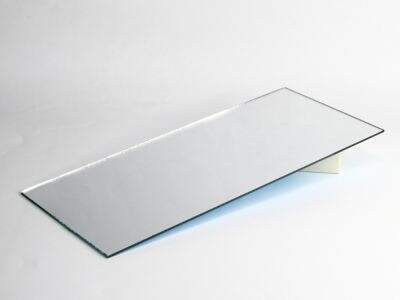

Optiske plader er nøgledelene for forskere og ingeniører, der arbejder i multidisciplinære områder, herunder mikroskop, lasersystem osv. Disse plader gør det muligt for os at se tingene med bedre klarhed og spiller en fremtrædende rolle i eksperimenter og teknologi. Men det kan være en udfordring at vælge en optisk plade, der passer til dine behov. Denne NOAIDA Derfor er det meget vigtigt at vide, hvad man skal kigge efter, når man vælger disse plader.

Hvornår blev optiske plader opfundet?

Der findes forskellige slags glas, når det kommer til optiske plader. Fælles Optisk objektiv typer er borosilikat, smeltet silica og kvarts. Hver slags glas har sine gode og dårlige sider. Som eksempel er borosilikatglas det glas, der er meget stærkt og ofte bruges til ting, der skal modstå pludselige temperaturændringer uden at gå i stykker. Men det er ikke så klart som kvartsglas, så du kan måske ikke se igennem det så godt. Fused silicaglas er på den anden side meget gennemsigtigt, hvilket tillader en masse lys at trænge ind, hvilket er fremragende til at observere subtile detaljer. Vær dog advaret, da denne type glas let kan ridse, hvis den ikke håndteres med omhu.

Sådan vælger du den rigtige størrelse og tykkelse

En anden faktor, du skal overveje, er størrelsen og tykkelsen af din optiske plade. Først og fremmest skal pladen være stor nok til dine behov. Hvis det er for lidt, vil det ikke give gode resultater for dit mål. Men hvis den er for stor, kan den blive uhåndterlig og umulig at bruge. Ud over størrelsen er tykkelsen en nøglefaktor, fordi den kan påvirke effektiviteten af pladerne. Jo tykkere pladerne er, jo stærkere og bedre kan de holde, men de kan også få billedet til at virke sløret eller forvrænget. Så det er for at finde en balance mellem størrelse og tykkelse, og hvordan du foretrækker at bruge pladen.

Hvorfor belægninger betyder noget

Så belægninger går på optiske plader for at få dem til at fungere bedre og have bedre ydeevne. For eksempel en anti-reflekterende belægning optisk filter påføres for at lade mere lys passere gennem pladen i stedet for at hoppe tilbage. Dette hjælper dig med at se bedre og få bedre resultater. Der er også polariserende belægninger, der forhindrer bestemte typer lys (enten indefra eller uden for enheden) i at trænge igennem og forstyrre det, du forsøger at opfatte gennem okularet. At vælge en belægning til dine optiske plader er, når det bliver bydende nødvendigt at overveje, hvilken type lys du bruger, og hvad du ønsker at gøre med pladen. At forstå dine særlige behov vil gøre dig i stand til at vælge den mest passende type belægning til din situation.

Vigtigheden af kvalitet

Når det kommer til at lave optiske plader, er kvaliteten i højsædet. Eventuelle fejl i den måde, de er fremstillet på, og pladerne vil ikke fungere, hvilket kan give problemer i dine eksperimenter eller hvilket projekt, du arbejder på. Et godt sted at starte din søgen efter et firma, som du kan købe dine optiske plader fra, er et, der har ry for at have produkter af god kvalitet. En ærlig person vil være i stand til og villig til at dele information om den slags glas, de bruger, de belægninger, de bruger, og de metoder og processer, de bruger til at lave deres tallerkener. Dette bør berolige dig om dit valg.

Tilpas tallerkener til dine behov

Når du har et udvalg af optiske plader, er det afgørende, at deres kvaliteter er afstemt efter det, du skal gøre. Til forskellige jobs eller eksperimenter har vi brug for forskellige slags plader. Visse applikationer kræver plader, der er usædvanligt klare og uforvrængede til visuel observation, mens andre kan drage fordel af specifikke belægninger til at bortfiltrere forskellige bølgelængder af lys. Når du kommunikerer med en producent, og de forstår dine specifikke behov og formålet med dine plader, kan de hjælpe dig med at vælge de mest passende optiske plader til dine behov.

Konklusion

Vi ved, hvor forvirrende det kan være at vælge mellem optiske plader, men det er afgørende at få det rigtigt for at levere lovende output i dit arbejde. Du kan finde de bedste optiske plader til dine projekter ved blandt andet at vide, hvad deres sammensætning er, deres dimensioner, tykkelse, belægninger og kvaliteten af pladerne. NOAIDA filter optisk tæthed er en førende producent af optiske plader, der bruges i en lang række applikationer i forskellige industrier. For at lære mere om vores produkter og hvordan vi kan hjælpe, kontakt os i dag. Så vi er her for at hjælpe dig med at finde de bedste løsninger til dine optiske behov.