-

+86-156 60188203

[email protected] - Dazhai, Nanyang City, Henan Province China

- Pazartesi - Cumartesi 8.00 - 18.00 Pazar Kapalı

Işığın çeşitli yönlerde nasıl gidebileceğini hiç merak etmiş misiniz? (duvara doğrudan çevirebilirsiniz — bazen, bir feneri açtığınızda ışık doğrudan ileriye gider, ancak duvara çevirdiğinizde ışık geri yansır ve yayılır) Işığın bu şekilde kontrol altına alınmasını sağlayan bir araçımız var ve bu araç da plaka ışık böleni olarak adlandırılır. Plaka ışık böleni, ışık ışınlarını iki farklı yola ayıran özel bir cam parçasıdır. Bu, ışığın ve çalışma şekli üzerine yapılan araştırmalarda son derece önemli bir unsur olup, aynı zamanda bilim insanlarına çevresini daha iyi anlamaları için olanak sağlar.

Plaka ışık bölmeleri yalnızca bir tarafta kaplanır. Kaplama bazı ışığı yansıtır ancak diğer dalga boylarını geçmeye izin verir. Aynı şey, bir ışık demetini ayna üzerine yerleştirdiğimizde de geçerlidir: bazı ışık yansırken, bazıları aynadan geçer. İlk olarak, plaka ışık bölmecisi: bir ışık demeti bunun üzerine çarptığında, iki demete dönüşür: biri yansıyan ve diğeri doğrudan geçen. İki ışık demetinden biri yeniden yönlendirilir ve plaka ışık bölmecisinden yansıma geçirilirken başka bir demet aynı dik açılı yolda ilerler. Bu oldukça önemlidir çünkü araştırmacılara ışık hakkında, rengi, nasıl seyahat ettiği ve farklı durumlarda nasıl davrandığı konusunda daha fazla bilgi sağlar.

Bir plak beamsplitter çok esnek bir optik elemandır. Örneğin: mikroskoplarda — bize çok küçük şeylerleri görebilme imkanı veren cihazlarda — gözlemlenen numuneyi aydınlatmak için çok az miktarda ışık gereklidir. Plak beamsplitter ile bölünen ışık, araştırmacıların numuneyi farklı açılardan gözlemleyebilmelerini sağlar. Bu da onlara inceledikleri şey hakkında daha fazla bilgi edinmelerine olanak tanır — örneğin, çok küçük hücrelerin şekli veya rengi hakkında.

Lazerler, odaklanmış ışık huzamı üreten ekipmanlardır ve de kullanılır kuytakam plakası . Lazer ışınlarını farklı ışınlara ayırmak için kullanılırlar ki bu, laseri odaklamak veya işaret ettiği şeyi değiştirmek için çok önemlidir. Bu, tıp gibi çeşitli alanlarda çok yararlıdır, burada laserler cerrahi prosedürlerde kullanılır ve teknolojide DVD oynatıcıları gibi aletlerde kullanılır.

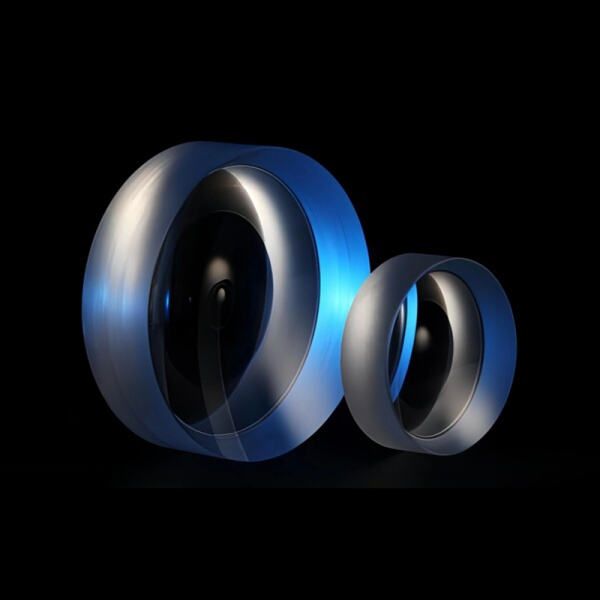

Bilim adamları, NOAIDA'nın güvenilir ve öngörülebilir şekilde çalışan yüksek kaliteli plak tabanlı ışık bölenler üretmesine güveniyor. Işık bölenlerimiz, performanslarını optimize eden özel bir kaplama olan üst düzey camdan üretilmiştir. Başka bir deyişle, bu ışık bölenler büyük miktarda ışıgyi yansıtabilirken aynı zamanda bazı ışığın geçmesini sağlar. Bu, bilim insanları için gereken bilgileri elde etmelerine yardımcı olduğu için önem taşır.

Ayrıca, noerida'nın plak tabanlı ışık bölenleri sert ve dayanıklı olacak şekilde tasarlanmıştır. Dayanıklı bir ürün tekrar tekrar kullanılabilen ve birkaç kullanımdan sonra bozulmayan veya işe yaramaz hale gelmeyen bir üründür. Bilim insanları çok zor ortamlarda çalıştığı için dayanıklı ekipmanlara sahip olmak kritik bir öneme sahiptir.

Bugün, plak tabanlı ışık bölenler kare prizma ışık bölenler kadar kritik bir öneme sahiptir. Bunlar temel algoritmaların daha ileri sürümüdür ve tıbbi görüntüleme gibi dokularımızı kesmeden vücudumuzun içinden daha iyi görüntüler elde etmeyi doktorlara sağlayan, aynı zamanda dünyaya yarım daire boyunca mesaj göndermenizi sağlayan iletişim gibi birçok alanda yaygın olarak kullanılmaktadır. NOAIDA'da, bu önemli sektörler için hassasiyetin hayati olduğunu biliyoruz. Plak tabanlı ışık bölenlerimizde üst düzey kaliteye odaklanıyoruz. Ürünlerimiz bilim insanları ve mühendisler için doğru ve güvenilir sonuçlar sunar. Bu, doğruluğun araştırma geliştirmesini ve teknoloji iyileştirmelerini destekleyebileceği için çok önemli bir konudur.

ISO9001 sertifikası ile birlikte Çin'in yuksek teknolojienterprise sertifikası yeni teknoloji, CE, SGS sertifikasyonu olan şirketimiz 300'den fazla tam ekipmanı sahiptir, bunların arasında 10'dan fazla araştırmacı bulunur. Plaka beam ayırıcılarının kalitesini garanti ediyoruz.

Şirketimiz satış ve pazar sonrası hizmeti 60'dan fazla çalışanla birlikte sunmaktadır. İhracat, ithalat ve uluslararası işbirliği konusunda zengin bilgiye sahibiz. 80'den fazla plaka beamsplitter üzerinde 3000'den fazla müşteriye hizmet veriyoruz.

Şirketimiz, müşterinin sketslerine göre optik prizmaları özelleştirme avantajına sahiptir, küçükten büyüğe kadar tüm boyatlarda. Çevrimiçi olarak mevcut üretim modellerinin sayısı 400'den fazladır. Plaka beamsplitter deneyimi çeşitli türden ürünlerin özel tasarım olması için işleme edilmesini içerir.

Nanyang Jingliang, 10.000 metrekarelik alana sahip bir optik bileşen üreticisidir. Şirketimiz mercek işleme, optik prizma üretimi, optik sistemler ve satış üzerine odaklanmıştır. Tüm plaka beamsplitter bileşen ihtiyaçlarınızı karşılayabiliriz.

Copyright © Nanyang City Jingliang Optical Technology Co., Ltd. All Rights Reserved — Gizlilik Politikası